DELIOS

DELIOS

- HERE YOU'LL FIND ALL THE INFORMATION ABOUT DELIOS ROTORS! -

ABOUT DELIOS

Delios began primarily as an aerospace engineering company in Melbourne Australia, which after popular demand by track customers developed & evolved into an automotive disc brake rotor manufacturer. Not happy to just run with the pack, we focus a vast amount of our resources into developing and maintaining a braking program that’s in a league of its’ own.

Utilizing over 20 years aerospace engineering knowledge & experience to research, design & develop brake discs for the automotive aftermarket. Delios brake rotors consist of a proprietary premium quality metal casting that is carbon enhanced and grain refined in addition to a unique manufacturing process to increase thermal resistance, performance & optimise endurance.

Over the years Delios has made its mark and continues to vastly expand in the automotive aftermarket industry as a high quality & innovative braking component manufacturer.

This remains our primary focus, we will only deliver the best of which is expected of Delios Brakes to our customers.

Over the years Delios has made its mark and continues to vastly expand in the automotive aftermarket industry as a high quality & innovative braking component manufacturer.

This remains our primary focus, we will only deliver the best of which is expected of Delios Brakes to our customers.

We offer the personal touch of a family-controlled business; focused on quality products, integrity, friendly service and timely delivery.

PROMEK STYLE

Designed to be the leading OE replacement rotor in the automotive aftermarket. Utilizing Symmetrical mould technology, each casting is designed to surpass the OE rotor originally designed for your vehicle. Attention to detail such as removal of all sharp edges, defined radius on opposing sides of venting, and burnished or double face ground finish on friction surface to ensure excellent pad bite from the very first application, are features included in every rotor. As with all Delios disc rotors, a proprietary blend of metals are used to create a wear resistant, noise dampening and thermally stable disc rotor.

Each disc is 100% measured and inspected to meet our strict tolerances and specifications.

What you will notice:

- More Bite

- Better Release Control

- More Stopping Power

- Increased Pedal Response

- Increased Corner Speed

- Longer life

- Noise level reduced for quiet braking

- Easy pad bed in through the use of double face grinding or burnished finish

- Extended service life of the wheel suspension and wheel bearings

COMMAND 4WD SERIES

4WD applications require unique solutions due to their low speed, high friction heat building properties, often due to oversized wheels and extreme downhill braking angles. Delios XP7 Command 4WD series rotors are engineered to facilitate heavy 4WD applications through the use of thermally stable, wear resistant, and stress relieved make-up of the disc and are uniquely out-gas vented to give the best clearance of water, debris and hot gasses often associated with 4WD activities. Command series is available with the durable, environmentally friendly Pro-Tekt coating or Geomet Coating.

What you will notice:

- Extra Bite

- More Release Control

- Additional Stopping Power

- Increased Pedal Response

- Increased Corner Speed

- More Endurance

- Noise level reduced for quiet braking

- Easy pad bed in through the use of double face grinding or burnished finish

- Extended service life of the wheel suspension and wheel bearings

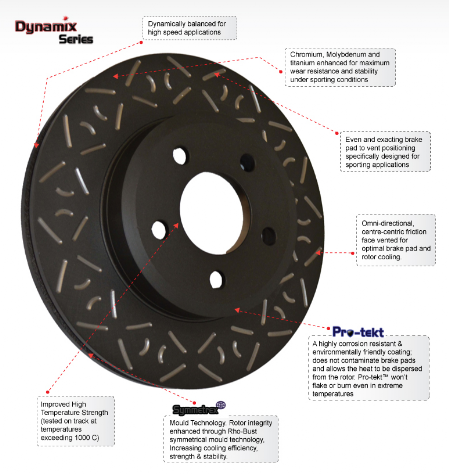

DYNAMIX

Dynamix takes sports disc rotors to a whole new level. Offering outstanding bite, thermal stability, wear and harmonic resistance. Out-gas vented in a unique and meticulously engineered pattern which provides the ultimate in rotor cooling technology designed to allow maximum ‘hot pocket’ relief of outgassing ( a leading cause of heat in a disc rotor) while eliminating the droning noise often found in less researched patterns. Dynamix rotors are then coated in the environmentally friendly Pro-Tekt process which gives it excellent corrosion resistance without the negative heat retaining properties often found in paints and other coatings. This will not chip, flake or burn off and is safe for even ceramic pad applications.

What you will notice:

- More Bite

- Better Release Control

- More Stopping Power

- Increased Pedal Response

- Increased Corner Speed

- Longer life

- Noise level reduced for quiet braking

- Easy pad bed in through the use of double face grinding or burnished finish

- Extended service life of the wheel suspension and wheel bearings